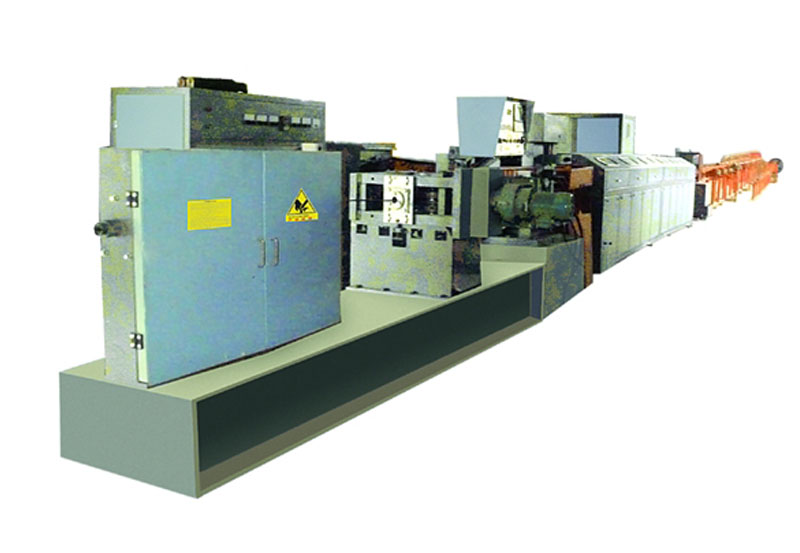

Brief introduction of unit configuration and performance

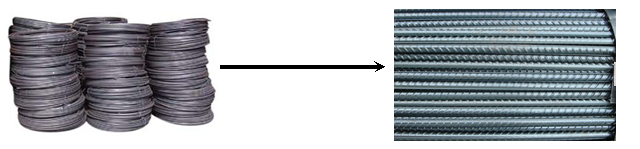

This machine is a special equipment for the production of cold-rolled ribbed steel bars

with two, the production line can be 6.5 Phi Phi 14mm Q235 hot rolled coil, cold rolled

steel (Figure 1) made of two crescent ribbed bar (Figure 2).

Figure 1 Figure 2 with two round steel

The complete set of equipment is composed of wire laying frame, whole wire cage, descaling

machine, rolling mill, main mill, straightening, heating, temperature measuring, shearing,

slideway, two side material receiving, pneumatic automatic pushing and take-up machine. The

unit is designed according to the continuous working system, and the whole set of equipment

is controlled by PLC system.

Here is a brief description of the structure and properties of each component:

(1) the function of the release frame is to ensure the high speed operation of the unit. It

consists of double discharge gun pipes, one is a work rack, the other is a storage rack, and

when one is in the line, the other barrel can be pre assembled. When working on the shelf

after the end of the coil, the coil coil and the other end welding rack hanging round

grinding, can continue to boot, then on another line to be pre frame material, this material

can be improved by pre design to reduce the work efficiency after stop charging.)。

(2) whole wire cage, electric top and bottom descaling machine;

The whole wire cage is welded by the threaded steel, and the funnel shape can change the

steel bar from the annular to the spiral straight strip, so as to ensure that the steel bar

enters the descaling machine before the descaling machine is basically straight and ensures

the high-speed and reliable operation of the machine.

Dustproof descaling machine consists of 5 blocks, the main function is the hot rolled coil

through the 5 round of descaling repeated bending surface oxide skin peeling, improve the

surface quality of steel, to reduce the effect on roll wear. The base plate is welded, such

as saving space, and can be mounted on a base with the mainframe.

(3) pay mill (see above)

The reinforcing bar is rolled and flattened by the rolling mill, and the main rolling mill

is prepared by rolling the thread, and the mill is made as a passive rolling mill.

(4) main mill

The main rolling mill is the last process of forming the thread steel. The rolling mill has

large force, and requires the high precision of the rolling mill and the following

advantages of the rolling mill:

1, center adjustment, (domestic unique) size of old and new roll, rolling center do not

tune.

2. The roller has a long service life and can be rolled up to over 10000 tons at one time.

3, roll replacement is convenient, (domestic unique) slideway, drawer type replacement, 10

minutes to fix.

4 、 automatic cooling system of main mill (unique in China).

5, a high degree of automation, (domestic unique) fully automatic concentric, for steel

import and export without adjustment, the world's leading technology.

6, the integration of high-precision guidance, (domestic unique) up and down around, a

guide can be achieved.

Computer numerical control automatic butter 7, unique to the system, the workers do not

timely solve the oil bearing damage (domestic only).

(5) console

The only console to mill, heating, blanking, cutting, feeding, and push down steel swing,

concentrated in a panel, truly integrated centralized control, to control the head on the

mill, do not account for the workshop position, can install more equipment in the limited

plant, using PLC program control system, touch screen display, can improve the stability of

equipment operation and intuitive display fault location through the touch screen.

Note: This equipment adopts infrared non-contact temperature measuring method, fiber

transmission, anti-interference ability, digital display temperature.

(6) heating cabinet (see general drawing above)

The biggest cost of operation of this set of equipment is electricity heating equipment,

steel is directly reflected in the consumption index, using high performance medium or super

audio heating equipment, can save 20 to 50 degrees / tons of electricity, require the use of

high performance RGBT module, power conversion efficiency, heating equipment, safe and

reliable operation, green environmental protection.

(7) shearing

Shearing adopts the flying shear developed by our factory. The shearing power is small, the

reaction is fast, the failure rate is low, maintenance free. After many years of

improvement, the technology is very mature and has the industry leading level.

(8) double flip and blanking system;

The system adopts the double cycle operation mode of (A, B, A), which can set parameters

separately, assemble the materials separately, and meet the demand of non stop baling.

Double feed rack (left and right) feed is a way to reduce downtime, bind and improve

production efficiency. After the steel bar is cut off, it falls from the tipping board and

is stored in the U type material receiving device, which is a reliable method for collecting

materials.

(9) leveling device (various pushing flat)

The steel bars fall into the aggregate rack, the length is not uniform, and they need to be

pushed flat. I design a pneumatic automatic flat pushing device, which can replace manual

pushing to eliminate unsafe hidden trouble, and how many roots can be pushed once.

Compared with the twin power cold rolling ribbed steel bar production unit, the single

power and the dual power have the disadvantages of two units:

1 、 butt welding is not firm and easy to break;

2, every time there is a strip of 10~20 meters of waste materials;

3, the roller is too large, easy to damage.

|

Product name

|

Company

|

Cold rolled two ribbed reinforced bar units

|

Cold rolled two ribbed reinforced bar units

|

Cold rolled two ribbed reinforced bar units

|

Cold rolled two ribbed reinforced bar units

|

Cold rolled two ribbed reinforced bar units

|

Cold rolled two ribbed reinforced bar units

|

|

Model

|

|

LMD10-9A

|

LMD12-10B

|

LMD12-10C

|

LMS12-10A

|

LMS12-10B

|

LMS16-14C

|

|

Diameter of base metal

|

mm

|

φ6-10

|

φ6-12

|

φ6-12

|

φ6-12

|

φ6-12

|

φ6-14

|

|

Diameter of finished product

|

mm

|

φ5-9

|

φ5-11

|

φ5-11

|

φ5-11

|

φ5-11

|

φ5-13

|

|

Roll line speed

|

m/min

|

120

|

150

|

180

|

150

|

180

|

200

|

|

Predetermined length

|

m

|

1~99

|

1~99

|

1~99

|

1~99

|

1~99

|

1~99

|

|

Length of chute

|

m

|

6~12

|

6~12

|

6~12

|

6~12

|

6~12

|

6~12

|

|

Blanking direction

|

|

Single direction blanking

|

Double blanking

|

Double blanking

|

Double blanking

|

Double blanking

|

Double blanking

|

|

Blanking sliding mode

|

|

360°rotate

|

360°rotate

|

360°rotate

|

360°rotate

|

360°rotate

|

360°rotate

|

|

Row spacing

|

mm

|

Accessories 5~20

|

|

Two times aggregate length

|

m

|

Matching length 6~12

|

|

Aggregate flattening method

|

|

Pneumatic automatic flat pushing

|

|

Adjust speed

|

|

Adjust speed

|

frequency conversion

|

frequency conversion

|

Frequency conversion

|

Frequency conversion

|

Frequency conversion

|

|

control mode

|

|

text+PLC

|

text+PLC

|

Touch screen+PLC

|

Touch screen+PLC

|

Touch screen+PLC

|

Touch screen+PLC

|

|

Cutting error

|

mm

|

±4

|

±2

|

±2

|

±2

|

±2

|

±2

|

|

Host power

|

KW

|

75KW

|

90KW

|

132KW

|

75KW+90KW

|

90KW+110KW

|

110KW+132KW

|

|

heating power

|

KW

|

300

|

400(500)

|

500(600)

|

500

|

600

|

800

|

|

Total power

|

KW

|

400

|

500

|

650

|

670

|

800

|

1050

|

|

Total weight (approx.)

|

Kg

|

6000

|

8000

|

14000

|

9000

|

16000

|

20000

|

|

Work area (including line release, minimum)

|

Length * width(m)

|

40×5×6

|

50×5×6

|

50×5×6

|

50×5×6

|

55×5×6

|

70×5×6

|

|

Stringing frame

|

|

Dual set

|

|

Line regulator

|

|

Accessories

|

|

rolling mill

|

|

Up sync compression

|

Electric automatic tuning

|

Electric automatic tuning

|

Electric automatic centering

|

Electric automatic centering

|

Electric automatic centering

|

|

Rolling times

|

|

2

|

2

|

2

|

2

|

2

|

2

|

|

Roll size

|

mm

|

Active millφ228

+Passive millφ155

|

Active mill228+Passive millφ210

|

Active millφ228+Passive millφ210

|

Active millφ228+Active millφ210

|

Active millφ228+Active millφ210

|

Main millφ228+Active millφ210

|

|

Straightening method

|

|

On line bar

|

On line bar

|

On line bar

|

On line bar

|

On line bar

|

On line bar

|

|

Take-up

|

|

Accessories

|

|

Φ6mReinforcement yield

|

Kg

|

1598kg/h

|

2000kg/h

|

2398kg/h

|

2000kg/h

|

2398kg/h

|

2660kg/h

|

|

Φ7mmReinforcement quantity

|

Kg

|

2170kg /h

|

2700Kg/h

|

3250kg/h

|

2700 kg/h

|

3250Kg/h

|

3620 kg/h

|

|

Φ8mReinforcement yield

|

Kg

|

2800kg /h

|

3555kg/h

|

4200kg/h

|

3555 kg/h

|

4200kg/h

|

4728 kg/h

|

|

Φ9mReinforcement yield

|

Kg

|

3500kg /h

|

4400Kg/h

|

5000kg/h

|

440Kg/h

|

5000kg/h

|

5988 kg/h

|

|

Φ10mmReinforcement quantity

|

Kg

|

|

5000kg/h

|

5500kg/h

|

5000kg/h

|

5500kg/h

|

6000 kg/h

|

|

Φ11mmReinforcement quantity

|

Kg

|

|

5500kg/h

|

6000kg/h

|

5500 kg/h

|

6000kg/h

|

7500 kg/h

|

|

Φ12mmReinforcement quantity

|

Kg

|

|

|

|

|

|

7000 kg/h

|

|

Φ13mmReinforcement quantity

|

Kg

|

|

|

|

|

|

8000 kg/h

|

|

Φ14mmReinforcement quantity

|

Kg

|

|

|

|

|

|

7000 kg/h

|

|

Φ15mmReinforcement quantity

|

Kg

|

|

|

|

|

|

8000 kg/h

|

|

Complete set of operators

|

People / Unit

|

3

|

4

|

4

|

4

|

4

|

4

|